INNOVATION AND TECHNOLOGY

Mixing equipment for the cosmetics, chemical, pharmaceutical and food

industry

Consorzio Monsaldo is highly specialized in realizing and providing customized stainless steel mixing equipment for the cosmetics, chemical, pharmaceutical and food industry. From design to final realization, Consorzio Monsaldo meets the highest quality standards and any specific need of the production process.

The equipment are always designed and manufactured in accordance with the guidelines and requirements of the customer, in line with the technical departments concerned.

Our mixing equipment are specifically designed for hot/cold mixing of liquid products up to high viscosity levels (beauty creams, gel, bath foam, liquid soap). The high technological level of design and implementation of the mixing equipment, allow to reduce production times, obtaining the maximum efficiency and a great optimizing of the production processes. All equipment are designed and constructed according to the Directive CE.

Capacity range from 1.000 to 16.000 liters

APPLICATION

Cosmetics

• Creams / Lotions / Gels

• Sunscreen / Sun spray

• Hair colors / Shaving foam

• Shampoos / Conditioners

• Liquid soaps / Bath soap

Chemical industry

• Adhesives

• Glues

• Paints

• Lubricants

• Car polishes

Pharmaceuticals

• Toothpaste

• Cough syrup

• Syrup

• Ointments

• Compounds

Food industry

• Confectionery fillings

• Sauces

• Dressings

• Toppings

• Dairy products

TECHNICAL SPECIFICATIONS

- Capacity range from 1.000 to 16.000 L

- Top grade certified materials:

– Stainless Steel AISI 316L for surfaces in contact with the product

– Stainless Steel AISI 304 for other components

- Tangential recirculate

- Central agitator with double acting anchors and blades with opposite grade

- Self adjusting scrapers Teflon made

- Mechanical set up for recirculating pump

- Mirror polishing of internal surface

- Bottom turbine

- Inlets for liquid products input

- Cooling/heating system in Stainless Steel AISI half pipe with pressure up to 12bar

- Cambered bottoms

- Mineral wool insulating and external finish in Stainless Steel AISI 304 seal welded, smooth and satinized

- Bent bottom flange to guarantee total liquid draining

- Man hole realized with fast closing system and vacuum proof gasket

- Temperature probe mounted on planking

- Actuated drain valve for product discharge

- Sampling valve

- CIP system with rotating cleaning heads

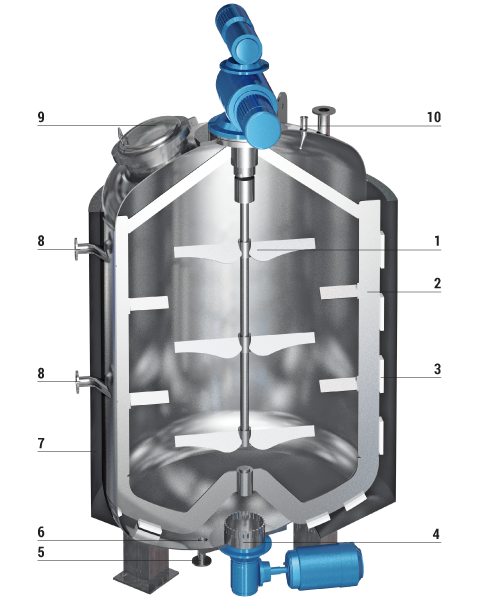

MIXING EQUIPMENT EXAMPLE

The components may vary according to the specific needs of the customer

Key

-

- Central agitator

- Double acting anchors with blades with opposite grade

- Self-adjusting scrapers Teflon made

- Bottom turbine

- Mechanical set up for recirculating pump

- Bent bottom flange to guarantee total liquid draining

- Cooling / heating system

- Tangential recirculate

- Man hole

- CIP system with rotating cleaning heads